When Do You Need a Soft Starter?

Soft starters have shown over time to be a pinnacle tool to help extend the life of our motor systems in the modern industrial world. The conventional method of powering up an AC induction motor is done by connecting directly across its 3-phase supply, and then the starter will apply the full line voltage to the motor terminals. This is commonly known as an “across the line” or “down the line” motor starter. This results in full power (voltage, current, and torque) being applied instantly upon turning on the motor, and likewise when the motor is turned off. While there are advantages and disadvantages to different types of motor starters, the high inrush current of this traditional method has been documented to damage the motor.

Today, we are going to look at the advantages of using a soft starter for your AC induction motor start-up.

What is a Soft Starter?

Simply, a soft starter works by having control of the amount of voltage running through the motor’s circuits. By effectively limiting the amount of torque in the motor, the soft starter can then reduce the applied voltage and will gradually stop reducing the voltage to allow for a smooth progression of current. During standard start up with a conventional motor starter an electric motor’s will require large amounts of electricity during acceleration to full speed, a soft starter can be used to restrict the inrush current and torque of the electric motor, lowering mechanical shock and creating in a safer and smoother start-up.

Soft Starter vs VFD (Variable Frequency Drive)

As mentioned above, a soft starter allows the user to gradually increase the voltage supplied to a motor when it starts, preventing the current and torque from building up too quickly. Alternatively, a VFD is a tool that controls the speed of the motor by adjusting the frequency of the AC supply power. Even though a VFD is primarily used for precision speed control, it can also sometimes be substituted as a soft starter and is ideal for applications where the acceleration characteristics must be highly consistent even with variable loads.

.

How Does the system Work?

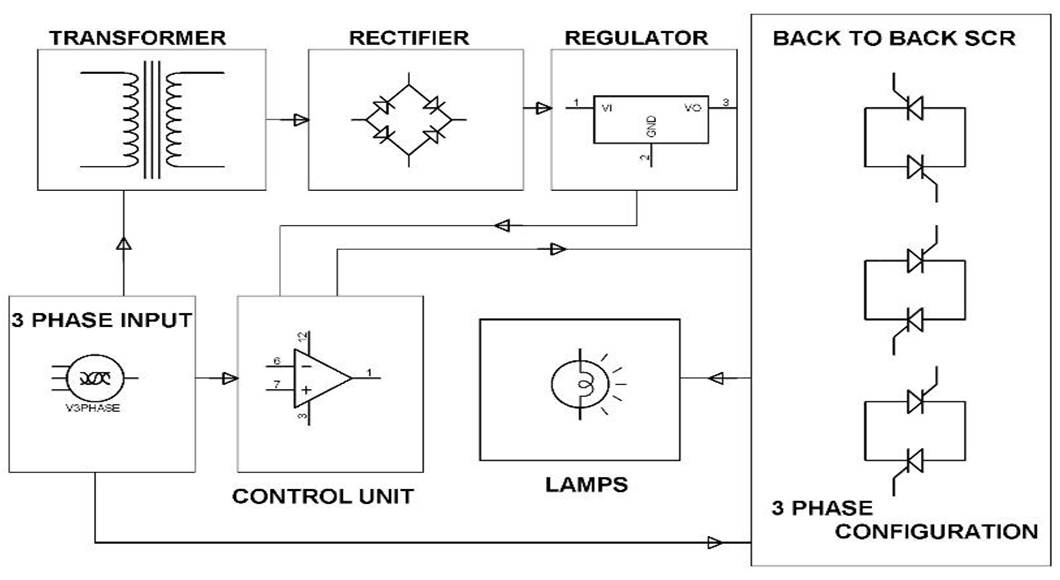

Soft starters control power applied to the motor using thyristors or silicon-controlled rectifiers (SCRs). For a 3-phase motor, two SCRs are connected back-to-back for each phase, or 6 in total. Power switches (like SCRs) need to be phase controlled such that they are applied for each part of the cycle. The switching devices need to be rated at least three times more than the line voltage. The SS uses control logic to fire the SCRs at correct times during the supply voltage cycle to create the appropriate output power profile. The SCRs are opened for longer as the motor torque increases, slowly increasing the pulse length until full power is supplied to the motor.

How Do I Know When I Need A Soft Starter?

Now that you know the benefits and functions of a SS, it begs the question: when do I need one? Does every motor require a soft starter? How do I know what type of soft starter to get?

Think of a soft starter as stretching before a big race… do you need to do it? Not necessarily, but it will help prevent damage done to your joints and muscles caused by explosive movement. No motor necessarily needs a soft starter, however, the energy savings and extended motor life make them a worthy investment for the majority of motor systems in the long run. Certain motors are more susceptible to breaking down and wearing out due to excess amounts of electrical current during their startup phase and will greatly benefit from a soft starter, including pump applications, converter belts, fans, and other similar systems. Soft starters introduce almost no harmonics into the system and typically have efficiencies of 99 percent or better.

Interested in a Soft Starter?

If you are interested in a soft starter for your motor system but are unsure about exactly what your best option is, we encourage you to reach out to us by giving us a call (780-968-8859) or by filling out our online contact form. Our team of experts will work with you to ensure the best option for your operations. Alternatively, click here to browse our full selection of WEG systems.