Benefits of DVDT Filters

Introduction:

As variable frequency drives (VFDs) become standard in modern motor control systems, their benefits – like energy efficiency and precision control – are well known. However, VFDs also introduce electrical challenges that, if left unchecked, can lead to premature motor failure. One such issue is steep voltage rise times, also known as dV/dt (change in voltage over change in time). To mitigate these harmful effects, dV/dt filters are a critical solution.

What is dV/dt?

When a VFD switches output voltage rapidly – often in the range of several kilovolts per microsecond – it creates sharp voltage spikes on the motor terminals. This phenomenon is called high dV/dt.

These fast-rising pulses can cause:

- Insulation stress – Rapid voltage changes can exceed the motor’s insulation rating, especially in older or standard non-inverter-duty motors.

- Partial discharge – Repeated spikes can break down insulation over time, eventually causing electrical failure.

- Reflected wave phenomena – In long cable runs, voltage reflections can amplify peak voltages at the motor terminals, sometimes doubling the expected voltage.

What are dV/dt Filters?

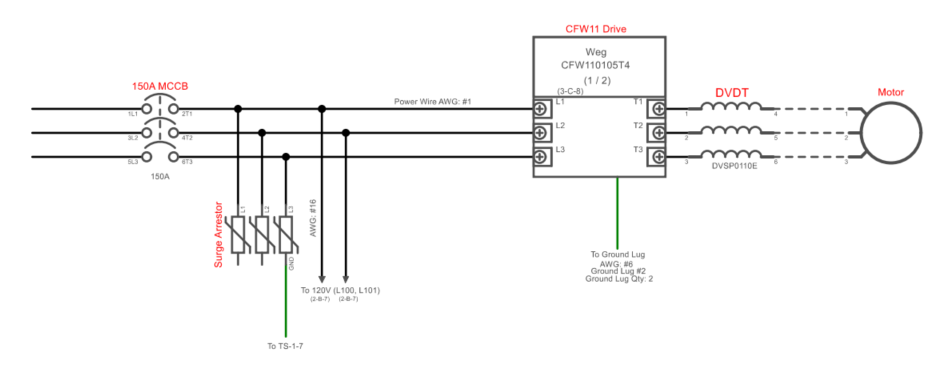

dV/dt filters are passive filters installed between the VFD and the motor. They smooth out the fast voltage transitions by slowing the rate of voltage rise (reducing dV/dt), protecting the motor’s windings from electrical stress.

Unlike sine wave filters – which convert PWM waveforms into near pure-sine waves – dV/dt filters are a simpler, cost-effective solution for reducing harmful voltage spikes without completely reshaping the waveform.

Benefits of dV/dt Filters:

- Protect Motor Insulation – By reducing the voltage rise rate, dV/dt filters extend the life of motor windings, especially in motors not rated for inverter duty.

- Support Long Cable Runs – In installations with long motor leads, voltage reflections are a major concern. dV/dt filters minimize the voltage overshoot at the motor terminals.

- Reduce Maintenance Costs – Avoiding insulation damage means fewer motor replacements, less downtime, and lower repair expenses over time.

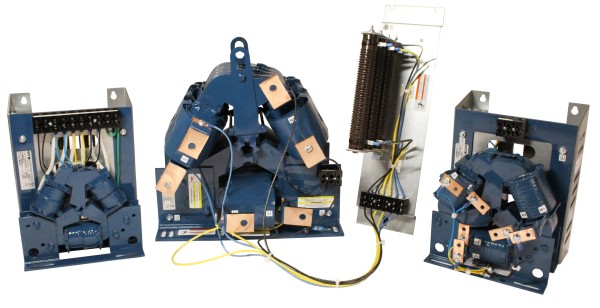

- Easy to Install – dV/dt filters are compact, air-cooled units that can be mounted directly between the VFD and motor – no special setup required.

- Improve System Reliability – Electrical stress is a silent killer in motor systems. dV/dt filters offer peace of mind by quietly preventing a common failure mode.

- Compatible with a Wide Range of Motors – Whether you are running standard induction motors, permanent magnet motors, or legacy equipment, dV/dt filters provide a layer of electrical protection without needing a full system redesign.

When to Use dV/dt Filters?

- When cable lengths exceed 50-100 feet

- When using standard (non-inverter-duty) motors with VFDs

- In systems with frequent motor replacements or insulation failures

- As a preventative measure in critical applications where uptime is essential

As VFD usage continues to rise, addressing the unintended side effects of high-frequency switching becomes more important than ever. dV/dt filters offer a cost-effective, easy-to-implement way to safeguard your motors from voltage-induced damage – helping your equipment run longer, more reliably, and with less maintenance.

Interested in a dV/dt Filter?

At Select Electrical Enterprises Ltd, we offer a wide selection of DVDT filters suitable for all your electrical needs. Feel free to reach out either by giving us a call (780-968-8859) or by filling out our online contact form.